HYPERXITE POD XI

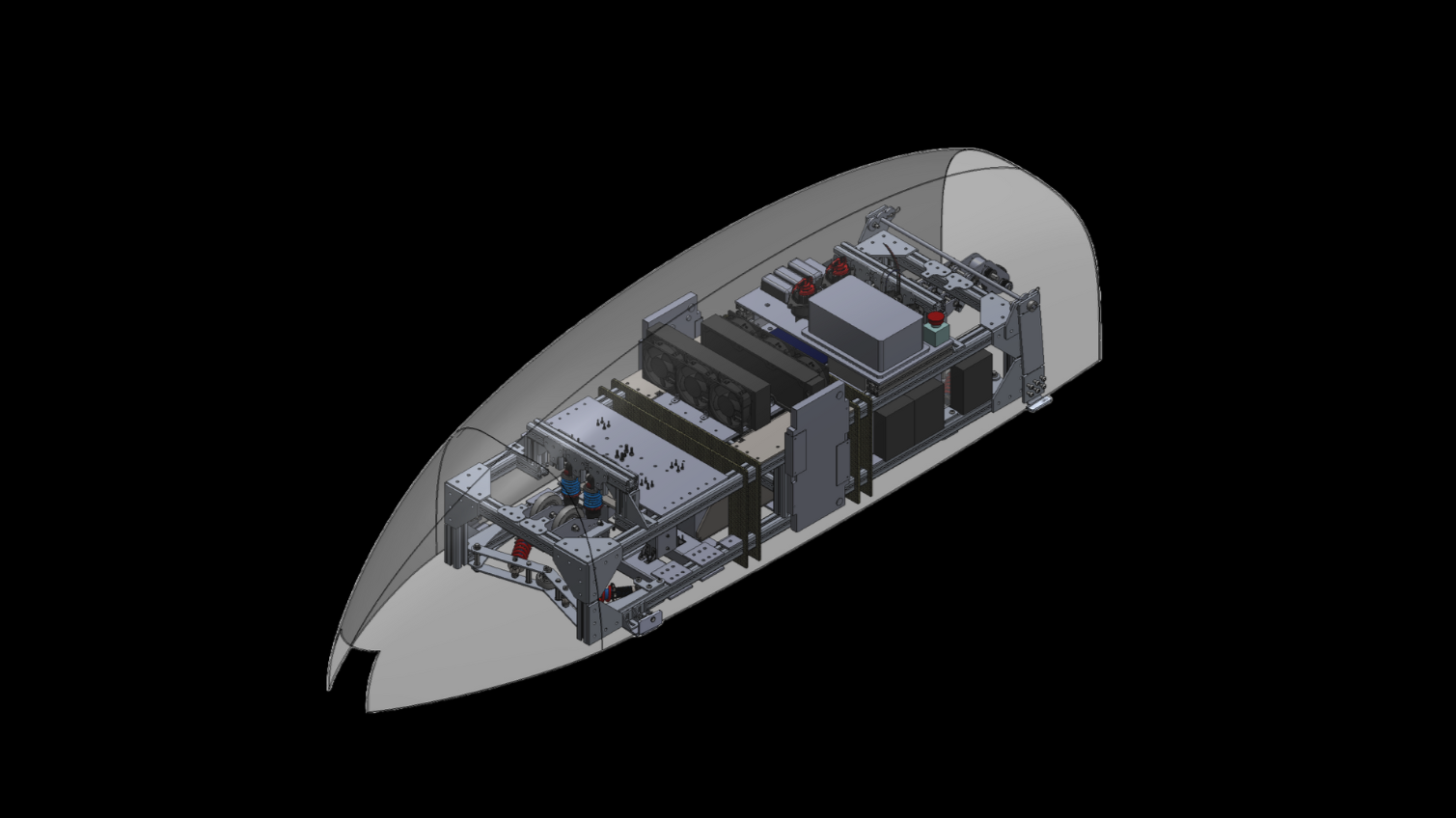

Aerodynamic structures

The Aerodynamics subteam focuses on designing and manufacturing the pod’s carbon fiber fairing to achieve maximum aerodynamic efficiency. Using Solidworks for geometric design and ANSYS Fluent for computational fluid dynamics (CFD) simulations, the team refines the fairing’s shape to minimize drag. Through extensive analysis and small-scale wind tunnel testing, the optimized design will be brought to life through precision CNC machining and in-house vacuum-sealed carbon fiber layup processes.

Static structures

The Statics subteam is responsible for designing and integrating the pod’s structural framework, supporting all subteams. Utilizing SolidWorks for CAD modeling and Ansys Mechanical for finite element analysis (FEA), the team analyzes the stress, strain, and safety factors to ensure the chassis can withstand both static and dynamic loads under high-speed conditions. This year’s focus is on refining the chassis design, improving mounting infrastructure for other subteams and optimizing space allocation within the pod.

DYNAMIC SYSTEMS

The Dynamics subteam is engineering a suspension system for the pod to enhance stability and maintain component integrity. By integrating springs, dampers, and mechanical linkages, the team aims to mitigate forces caused by I-beam irregularities and ensure continuous rail contact. Creating detailed Simulink models to characterize the pod’s vibrational response allows for further refinement in suspension parameters optimizing the pod’s overall dynamic performance.

BRAKING and pneumatics

The Braking & Pneumatics subteam is developing a pneumatically actuated friction braking system to ensure safe and controlled deceleration of the pod. By integrating actuators and gas springs, the team converts pneumatic energy into spring force that applies frictional braking through brake pads. Using Ansys and SolidWorks for design and finite element analysis (FEA), the team aims to achieve precise braking performance with stopping distances that exceed a safety factor of 2.

Thermal cooling

The Thermal Cooling subteam is undergoing significant design alterations by developing an active liquid cooling system for the Linear Induction Motor (LIM). Using SolidWorks to model electromagnetic coils and Ansys Fluent to simulate fluid flow and thermal behavior, the team will focus on optimizing heat dissipation through forced convective cooling. This will ensure the LIM operates safely and improve the pod’s overall power management mechanical integration.

levitation Research and Development

The Levitation subteam conducts research and development in electromagnetics and control systems for a magnetic levitation system using Ansys Maxwell and COMSOL Multiphysics, while also collecting and analyzing experimental data through sensors and coding in C, C++, and Python to refine performance and system stability.

Power Systems

The Power Systems subteam constructs a PCB that facilitates the pod’s Variable Frequency Drive and engineers a fail-safe using a Battery Management System device to prevent operational hazards and ensure reliable system performance.

Operations

The Operations subteam establishes and maintains communication with corporate sponsors and HyperXite alumni, manages all HyperXite social media platforms, and coordinates and leads planning efforts for the team’s annual Demo Day event.

Propulsion

The Propulsion subteam is in charge of engineering a three phase, double sided Linear Induction Motor (LIM) to serve as the pod’s primary propulsion system. By simulating electromagnetic behavior through Ansys Maxwell, the team aims to maximize efficiency and performance. In addition, the team is establishing testing procedures to ensure the system’s reliability and scalability for high speed operation.

Control Systems

The Control Systems subteam integrates mechanical and electrical subsystems, manages sensors through a finite state machine coded in C++, and provides remote operation via a control station that delivers real-time data through a graphical user interface..